J P EXTRUSIONTECH LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to J P EXTRUSIONTECH LTD.

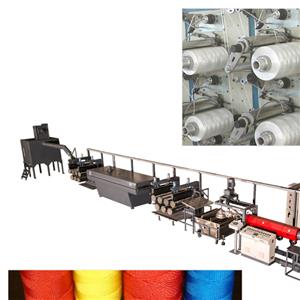

Bag Conversion Lines

JP developed Conversion lines for producing bottom folded and sewing woven sack made from a roll of tubular woven PP/HDPE fabric. JPBCL – 850 model from J P EXTRUSIONTECH LIMITED is a high-speed machine suitable for conventional bag application and is designed for cutting the tubular fabric, bottom folding, sewing, and stacking. This new generation machine with servo and PLC controls is designed for fabric width up to 850 mm and cut length up to 1400 mm with speeds up to 30 to 40 bags/min. Depending upon the material, width of the fabric, length of the bag, number of folds, stitches etc. This bag making machine is most appropriate for working with un-laminated fabric but can also be converted to use laminated fabric.

Advantages of this conversion Line:

- State of the art automated operation & consistent quality of end product (cut & sewn bags.)

- Reduced space requirement in finishing department for converting the roll of fabric to the finished bag.

- Reduced manpower requirement for producing the same quantity of bags.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.